|

THE HISTORY OF ST. JOE LEAD

COMPANY |

|

THE HISTORY OF ST. JOE LEAD

COMPANY |

The story of St. Joe is of a relentless and successful search for new

mineral deposits, of finding better ways of taking ore from the ground, of efficiently

processing it into useful industrial materials and of developing new and larger markets

for its commodities. The story of St. Joe is

also the story of the personalities who initiated and developed the mining operation and

lent culture to an isolated spot in the hills of

St. Joe’s story began on

|

Since lead had been mined in southeastern

|

A young lawyer by the name of J. Wyman Jones with a modest practice in

Seeing a notice in a

A most discouraging picture was painted and many of the stockholders learned for

the first time the encumbrances upon their property. So

many embarrassing questions were raised that the meeting was adjourned. At a reconvened meeting, Mr. Jones was asked to

visit the property in

Arriving in

Successive years did not lessen the problems – only changed them. Again Mr. Jones reported, “it will be readily seen that the labor involved in blasting, moving, breaking, crushing, jigging and smelting ores was quite out of proportion to the value of say 2,300 pounds of lead per day at five cents a pound, and that we derived little encouragement in the way of profits.”

“Some of the greater difficulties then encountered in working the mines profitably are not apparent from the above account of dressing and smelting of ores. All the ore was taken from open cuts or surface shallow shafts. In wet weather, the miners could not work in them because the cuts were full of water. In winter the sleet and ice interfered with work. In dry weather, as we depend upon rains for the necessary water for dressing the ores, we could not “jig” or crush that for want of water. Hence, with all our earnestness and energy, we could not do more than about six months’ work in a year, far too little to cover expenses.”

Equipment was crude and inefficient. Furnaces were old-fashioned stone ovens, which sloped to the front with a large firebox for wood beneath. Separation of the rock from the lead was done by a process called “jigging.” The jigging machine, used at that time, is described as a long heavy pole lying across a large log or wooden horse with a water-washed sieve filled with crushed ore. Constant short, sharp motions by a man on the end of this pole would move the material in the sieve up and down in the water. The heavy particles of lead would sink to the bottom while the lighter particles of stone would remain at the top.

In 1865, two blast furnaces were erected for smelting of lead but were not satisfactory and were abandoned. In early 1866 a reverberatory furnace the output of pig lead could be increased as far as it was practicable to hire and accommodate men.

From a copy of the report to the stockholders for 1866 we find that a new Resident

Superintendent, J. C. Winslow, was employed for the

Two hundred fifty tons of pig lead was sold in 1866, which was more than double the sales of the previous year.

President Jones was exhausted and thoroughly worn out with the many trials and

tribulations he had encountered as head of the mining venture in the wilderness of

It was here that Mr. Jones met Dr. Charles Bunyan Parsons a man who was to play an

important role in the development of the lead mining area in southeast

|

Dr. Parsons’ education was in the field of dentistry. He set up his office in

Persuaded by his doctors that he must get into some profession where he could be

out of doors more than his dental practice would allow, he accepted a job with a small

mining company in

During many of the evenings in

Toward the end of Mr. Jones’ vacation he asked Dr. Parsons if he would make a

trip to

Finding a convenient time to make the trip, Dr. Parsons made a close inspection of

the southeast

Dr. Parsons was offered the position of Resident Manager but hesitated to accept until he had discussed it with his wife. He had married a very charming lady in 1862 and he felt that it was beyond all decency to drag her so far from things that she had been used to and set her down in a wilderness where there was little else than mud and a few log cabins. He asked for more time before giving his answer to which the Board readily agreed.

Dr. Parsons was inclined to accept this challenge of his skill and ability but he

cautiously outlined the proposal to his wife Jane with the full expectancy that she would

refuse to go to the wilderness of

On the first of May in 1867, Dr. Parsons associated himself with the company and he

and Mrs. Parsons started on the long trip to

The “Works” consisted of one small crushing mill, one set of Cornish

rolls, three reverbertory furnaces and a few hand-operated jigs.

Dr. Parsons’ first efforts were to increase production. More pumps were purchased to keep the inclined pits dry so work could continue daily. Several more furnaces were installed and the “Parsons Mechanical Jig” was installed which was an improvement over the one-man job.

There is no doubt but that the enthusiasm and wisdom which Dr. Parsons brought to

Perhaps it could be expected that Dr. Parsons’ increased expenditures would be questioned by some of the stock-holders. They had already expended more than they felt justified in doing and hesitated to throw more money into the business. This created quite a hassle, but Dr. Parsons ultimately proved himself right by processing enough lead to pay a small dividend. This small dividend persuaded the Board of Directors to issue one hundred thousand dollars worth of bonds, which were sold to the stockholders. In January of 1868 the company was free of debt with the exception of that owed the stockholders.

As mining activities continued, it was found that by sloping underground a better grade of ore was encountered and much better protection for the men was provided from the inclement weather. Another economic advantage resulted in that the overburden of dirt was not removed. Men were able to work successfully the entire year.

One of the locations known as “1095” or the Bonne Terre supply shaft, produced good ore as far down as thirty-five feet in the clay and seemed to get better toward the bottom of the drift, with lead ore imbedded in it, convinced Dr. Parsons that good values lay in the rock further down. With sledge hammers and drills they continued downward using black powder to blast the lead contained rock. This is perhaps the first record of “hard rock mining” in this district.

Dr. Parsons immediately wrote President Jones regarding the experiment in hard rock mining and asked permission to continue the experiment.

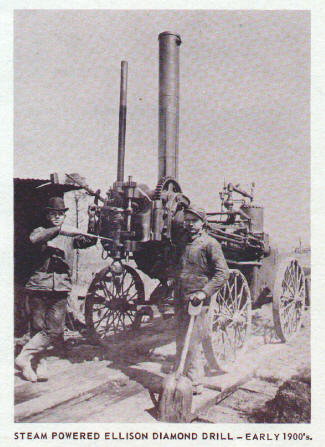

Dr. Parsons had read an article in a magazine regarding a new invention called a diamond drill. This device would cut deep into the rock and bring up samples of the rock through which it had drilled. Mr. Jones felt this device seemed to have application to the lead mines. He owned a plot of land near Peekskill-on-the-Hudson under which was reported to be a valuable body of find marble. He contacted the inventors, Severance and Holt, and contracted them to drill his property. The fact that the diamond drill proved the marble was of no particular value convinced Mr. Jones that his device had great possibilities for the lead mines.

|

He presented his report regarding the diamond drill to the stock-holders hoping

that they would approve the necessary money to move the drill and an experienced driller

to

Mr. Jones had one enthusiastic backer in Mr. Hugh N. Camp, Sr., Treasurer of the company, who agreed that although much ore was in sight there was nothing to prevent the company’s expansion. Increasing the output of the mines would thus earn additional money.

Mr. Jones and Mr. Camp advanced the necessary funds to move the drill to

The discovery of new ore bodies and increased production necessitated drastic changes in the smelting process. Several types of furnaces had been tried and none proved too satisfactory.

Mr. Gustave Setz, a highly skilled metallurgist from

With the increase in production and sales, it soon became apparent that the

construction of a railway was an absolute necessity. Numerous

attempts had been made to find a satisfactory route to replace the crude wagon

transportation used by St. Joe. The wagon

roads, if they could be called roads, were mere tracks through the woods. After some use, these roads became continuous mud

trenches. When the teams pulled heavy-laden

wagons through these trenches, the wheels often sank up to the axles. Hauling was slowed to such an extent that it became

impossible to secure enough teams to handle the job. The

much-needed railroad, some 13 � miles, was completed in January 1880 to the

|

The annual reports to the stockholders for 1880, 1881 and 1882 each reported material gains in metallic lead produced and sold. The 1882 report states that production reached a high of 15,214 pigs of lead weighing 81.5 pounds each. Net profits for the year were $200,000.

At this point in history of the company when many of the problems seemed to have

subsided and profits were on the increase, a major disaster occurred. It was a cold Sunday morning,

The

The smelting of lead required many cords of wood daily making it necessary that the company own large acreages of timberland. One such acreage was a 344-acre tract called Penn Diggins, which later proved to contain a very rich deposit of lead. In 1886 the Penn Diggins shaft was sunk and the lead produced from this tract not only made it possible to pay for the new mill, but also financed the building of a new railroad connecting the Lead Belt and the Mississippi River and thereby effecting a drastic reduction in shipping costs.

Other acquisitions of land in the vicinity of the present town of

Since the Hunt and Hoffman tracts were producing large amounts of ore, it was decided to build a processing mill. By the spring of 1904, a new 1200-ton capacity electrically operated mill was in operation.

A branch of the

A switchback was in use north of

The St. Joe venture in

|

In the same year Mr. Jones, with other Trustees, formed the Doe Run Lead Company, which was subsequently absorbed by St. Joe.

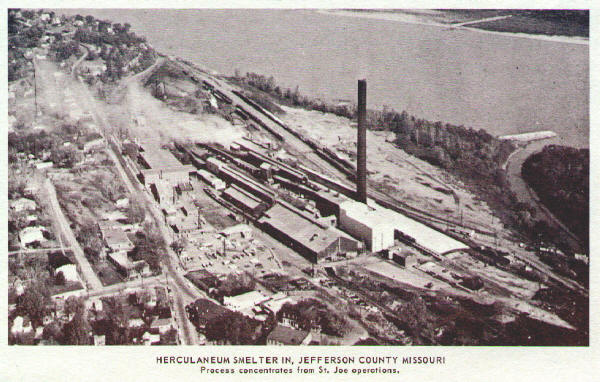

In 1890, St. Joe began construction of the large smelter at

|

During the early 1890’s many new mining companies were formed in

Some of the newly formed companies in

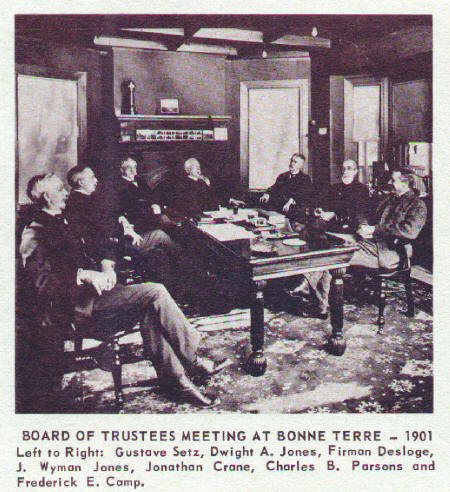

Mr. Wyman Jones died on

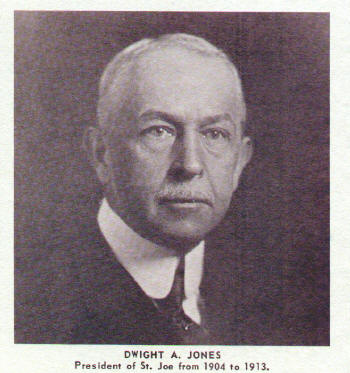

Dwight A. Jones, who had been with the company nine years as Secretary and Trustee, succeeded his father as President.

|

The problems confronting him were quite different from those that the founders had

faced. The chief difficulty was to maintain

the Company’s momentum. Dwight Jones

overcame this obstacle with conspicuous success. He

saw clearly that the Company would have to acquire new properties and build new plants to

meet the rapidly changing conditions of the new century.

This was not always easy. Aggressive

new mining interests had come into southeastern

|

In 1907 Panic set in motion forces that created new problems for the industrial community. During the next four years, St. Joe and Doe Run (then still a separate entity) ran up short-term debts totaling more than $8,000,000. Dissatisfaction was expressed vigorously by a minority of stock-holders, and St. Joe became involved in litigation and controversy that for awhile threatened its existence. The Doe Run Lead Company was merged into St. Joe and the Company went ahead on an entirely new footing.

At this point in the history of St. Joe,

At the annual meeting of stockholders in 1910, Mr. Roscoe R. S. Parsons was elected a Trustee of the Company and appointed Resident Manager to succeed his father.

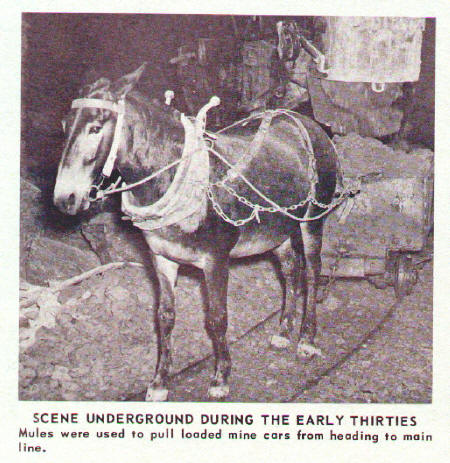

Roscoe Parsons made many changes in an effort to effect improvement in operations and to improve economics. Air locomotives replaced mules in 1911 on the mainline haulage at Leadwood. The Bonne Terre mill was equipped to operate electrically. Electric motors replaced the outmoded steam engine.

Mr. Dwight A. Jones, who had served as President of the Company since his

father’s death in October 1904, died

|

Mr. Clinton Hoadley Crane was elected President of the Company on

He also had the same gifts as his predecessors – the capacity to grasp important issues and the ability to select capable men to weld together an efficient organization. Mr. Crane was insistent on studying the problems himself so he made frequent trips to the Lead Belt, making detailed examinations of St. Joe’s procedures as well as those of its competitors.

During the latter part of 1914, Mr. Crane brought to the Lead Belt, Mr. Charles J.

Adami, of

|

On

|

By the end of 1915, two years after Mr. Crane had taken office; St. Joe had paid

off practically all its debt. It was

modernizing its methods, notably by introducing the flotation technique in its

concentrating mills, effecting substantial savings. It

had established its own sales force, a far-reaching step which did much to fortify and

extend the already high reputation enjoyed by St. Joe products throughout the

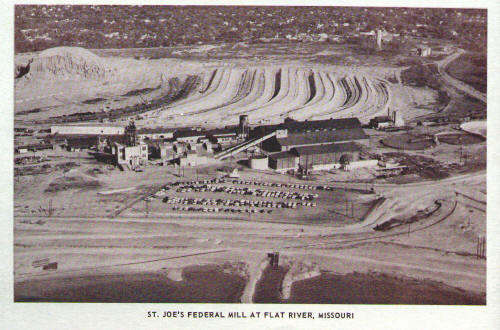

Progress and Expansion were steady throughout the years of World War I and the

pre-Depression era. St. Joe acquired a number

of mining properties in the Lead Belt, the most important of which was the Federal mine,

purchased from the American Smelting and Refining Company in 1923. It expanded its underground rail system and

consolidated these properties, including the Federal mine, into a network of more than 250

miles of narrow gauge track, running under the towns of

|

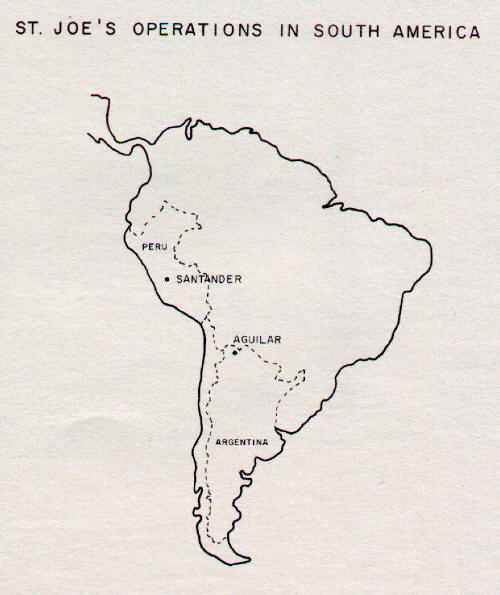

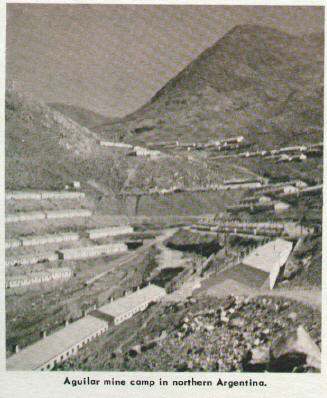

During Mr. Crane’s administration in 1925, St. Joe became interested in foreign operations and investigated an outcrop of lead ore that had been discovered about 2,000 feet below the summit of a 17,000 foot mountain in northern Argentina, not far from the Bolivian border. After extensive exploration, which revealed the presence of a rich lead-zinc-silver orebody, the Company exercised its option on the property.

|

Today, the Aguilar mine not only is

a most important mining operation in

|

Another important development during Mr. Crane’s long administration was St. Joe’s entry into the zinc field.

|

The Edwards and Balmat properties in

upstate

|

A smelter at Josephtown was built by St. Joe to produce zinc oxide and later zinc metal from the concentrates supplied by the Edwards and Balmat properties.

|

Going into the thirties or Depression era, St. Joe like many other companies, was confronted with little or no sale for its products. Rather than close operations, as many did, St. Joe in 1932 curtailed its operations to one week per month. During the summer months, St. Joe provided garden spots for employees that they might raise food for their families. During the winter months permission was given to cut wood off company lands for heating and cooking purposes. During the depression years St. Joe borrowed $10,000,000 and stockpiled thousands of tons of lead concentrates in order that each employee might have some money for his family needs.

Operations were back to a five-day workweek schedule by the end of 1936. Operations were changed to a six-day every other week work schedule in the spring of 1938.

Hitler and his German army were on the move in

With the World War II years to follow, things sky-rocketed all over the country. St. Joe had in excess of 3,000 payroll employees working in the Lead Belt area by the end of 1945. It was during these years that the payroll employees became unionized.

|

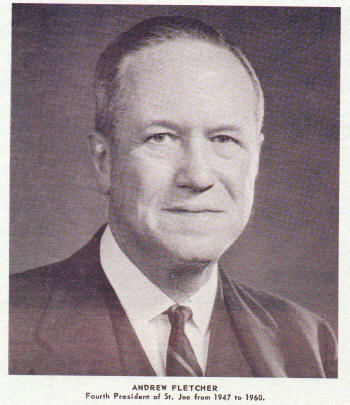

Mr. Crane was succeeded as President in 1947 by Mr. Andrew Fletcher, a graduate in

mechanical engineering from the Sheffield Scientific School of Yale University. Mr. Fletcher had been a Trustee of the Company

since 1921 and was Vice President and Treasurer of the Company from 1929 until 1947. Mr. Fletcher served as President until

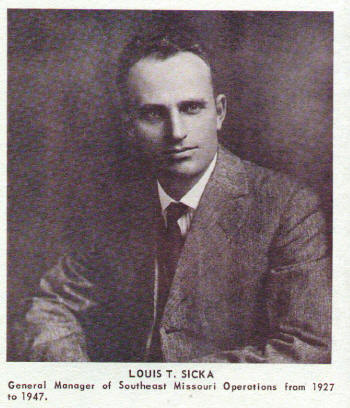

Mr. Louis T. Sicka, who had succeeded Mr. Adami as General Manager of the

|

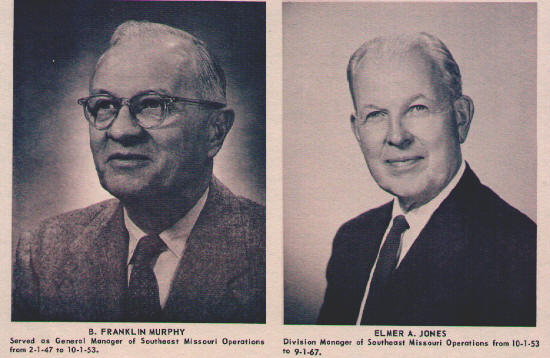

Mr. B. Franklin Murphy was appointed General Manager, replacing Mr. Sicka on

Mr. Elmer A. Jones became Division Manager of the

|

While serving as Division Manager, he initiated many changes and innovations; the

first trackless mine in

|

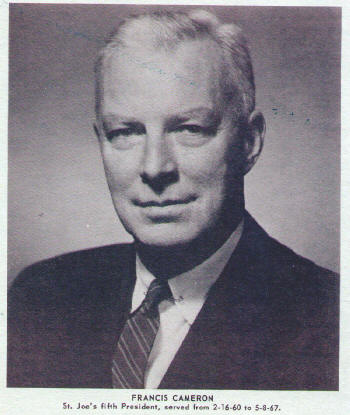

Mr. Francis Cameron was elected President of the Company on

|

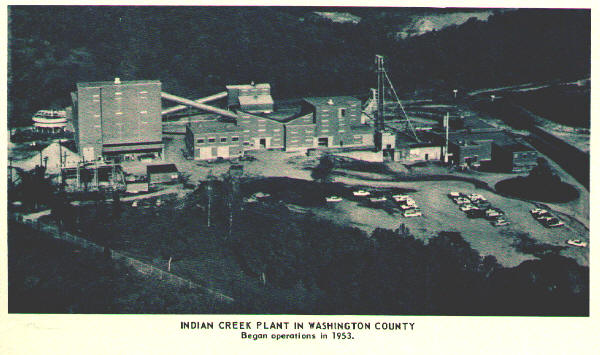

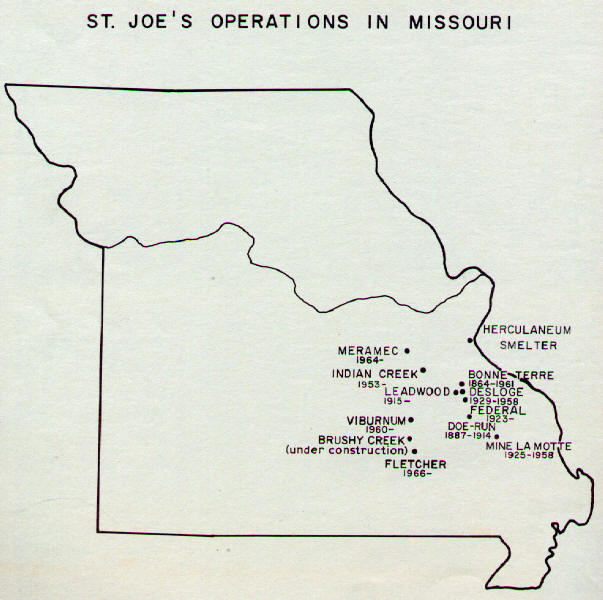

Indian Creek was the first of the major new lead mines in southeastern

|

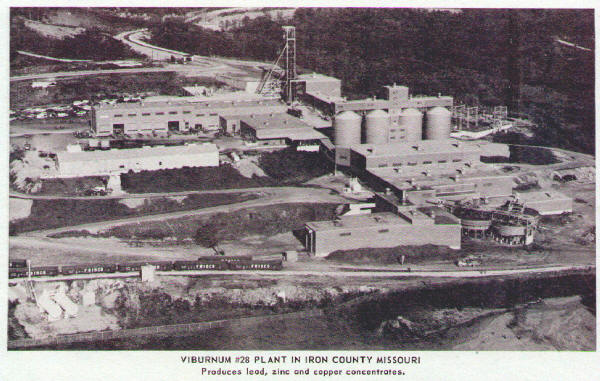

The Viburnum plant which began production in 1960 was regarded at the time as one

of the most modern and efficient lead mining and milling installations in the world. The No. 27 mine is located at

|

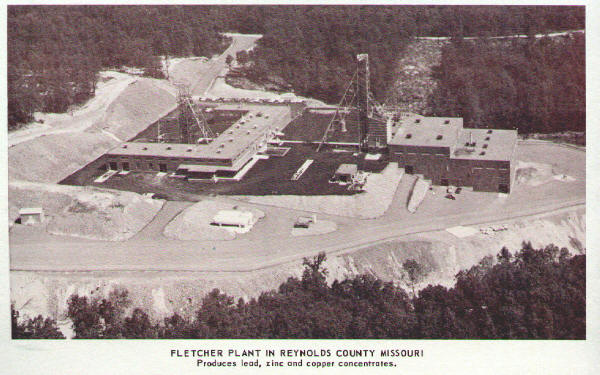

The Fletcher plant is located in

|

Mr. Cameron was awarded the Saunders Medal for “distinguished administration in finding and development of new mines and for inspiring leadership in the non-ferrous industry.”

Mr. Cameron succeeded Mr. Fletcher as Chairman of the Board of Trustees on

|

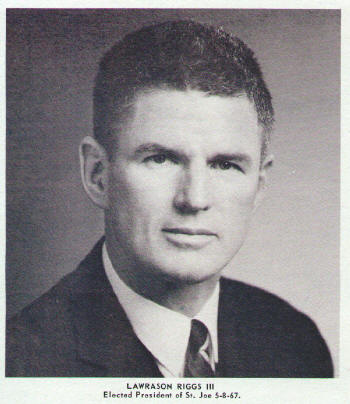

Mr. Riggs attended

Mr. Riggs started his career with St. Joe as a summer employee in 1936 at Balmat,

N. Y. He began regular employment at the Bonne

Terre mine

|

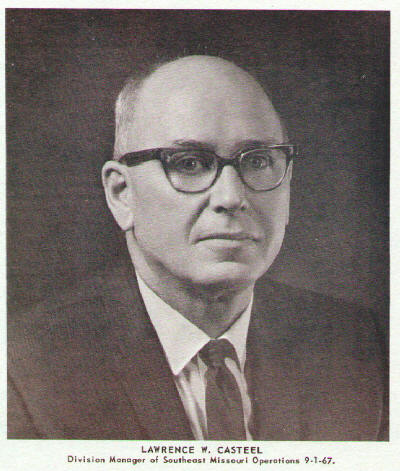

Mr. Lawrence Casteel assumed the position of Division Manager of the Southeast

Missouri Mining & Milling operations on

Mr. Casteel is a graduate of the

His first employment was on

|

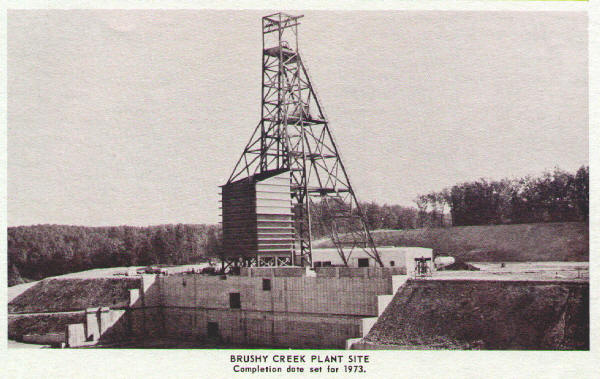

The company is continuing its expansion. A

site is being cleared for a new mine and mill to be known as Brushy Creek. This site is located approximately six miles north

of the Fletcher plant in

|

As we move forward in the second hundred years of mining, we know we cannot rest on

our past success. Our leaders today, like

those of the past, are men of vision with optimism, foresight and determination that St.

Joe will always be a leader in the mining industry.

| This issue of the Headframe is devoted to the history of the St. Joseph Lead

Company. In the interest of progress this name is gone from the "Big

Board" at the New York Stock Exchange, but in the memories of many, it will live on,

and the St. Joe Minerals Corp. will forever remain a stranger. One hundred six years

of successes and failures and hopes and dreams can be erased only by the passing of a

generation. For many the events and names mentioned in this issue will recall nostalgic memories of good times and of bad times; of jokes and fun; of hard work and blistered hands; of accidents and misery; of friends and nicknames - but the list is endless. Enjoy this issue. We shall not look back often. If we did, we might shed a tear and sentiment has no place in business. Or does it? Larry Casteel |

Special thanks is given to Mr. Henry C.

Thompson, St. Joe Pensioner and member of the Missouri Historical Society, for his very

helpful hand in compiling this history of St. Joe. |

Many thanks to Jeannie Hunt Nassaney for transcribing the above article for us!!

The information on this site is provided free for the purpose of researching your genealogy. This material may be freely used by non-commercial entities, for your own research. The information contained in this site may not be copied to any other site without written "snail-mail" permission. If you wish to have a copy of a donor's material, you must have their permission. All information found on these pages is under copyright of Oklahoma Cemeteries. This is to protect any and all information donated. The original submitter or source of the information will retain their copyright. Unless otherwise stated, any donated material is given to MOGenWeb to make it available online.